IH型卧式单级化工泵

浏览量:4541

一、产品概述:

IH型卧式单级化工泵根据国际标准ISO2858所规定的性能和尺寸设计,其技术标准均向国际标准靠拢,达到国际先进水平。它是我国推广的节能泵类产品之一。IH型卧式单级化工泵结构简单,性能可靠,体积小、重量轻,抗腐蚀性能好,电耗低,使用维修方便。IH型卧式单级化工泵通用性广,它有29个基本型,其中22个双速(2900、1450r/min)经过A、B两种型式的叶轮直径切割变型后,达140个规格,但只用四种轴;同一规格的轴,轴承、轴封、叶轮紧固件等均能互换;全系列泵的悬架也只有四种。

IH型卧式单级化工泵材质:由于该型泵主要用来输送腐蚀性介质,所以其过流部件(即泵体、泵盖加叶轮)均采用以下不锈钢材料。用户如需选用其它特殊材料,请于订货时事先提出。

用户可根据被输送介质的腐蚀性程度对泵的过流部分主要零件选用不同材料。泵的过流部分IH型卧式单级化工泵输送介质温度为-20℃~105℃,需要时采用双端面密封冷却装置,可输送介质温度为20℃~+280℃。适用于化工、石油、冶金、电力、造纸、食品、制药、环保、废水处理和合成纤维等行业用于输送各种腐蚀 的或不允许污染的类似于水的介质。

特殊情况(高温、高压及特殊材料)请于订货时预先提出,以便提供更为可靠之产品。

二、适用范围:

IH型卧式单级化工泵适于化工、石油、石油化工、冶金、轻工、印染、制药、环保、海水淡化、海上采油、造纸、食品等工业部门输送不含固体颗粒的有机式无机化工介质,石油产品及腐蚀性的液体。

三、工作条件:

1.可输送水类物质及各种腐蚀介质(粘度类似水);

2.密度范围P=1.0~1.84×103kg/m3;

3.介质温度在-20℃-160℃范围之间;

4.系统工作压力≤1.6MPa,即:系统压力=吸入口压力+泵闭阀工作时的压力≤1.6MPa;

5.流量3.4-460m3/h 扬程H3.6-132m;

四、型号意义:

IH 100 - 80 - 160 A

IH - 国际标准卧式单级单吸化工泵;

100 - 吸入口直径(mm);

80 - 排出口直径(mm);

160 - 叶轮名义直径(mm);

A - 叶轮外径切削次数;

五、产品特点:

IH型卧式单级化工泵具有水利性能布局合理、可靠,体积小,质量轻,抗汽蚀性能好,电耗低,使用检修方便,工作效率高等优点。

IH型卧式单级化工泵为卧式结构,其结构设计基本能满足所有管道安装。

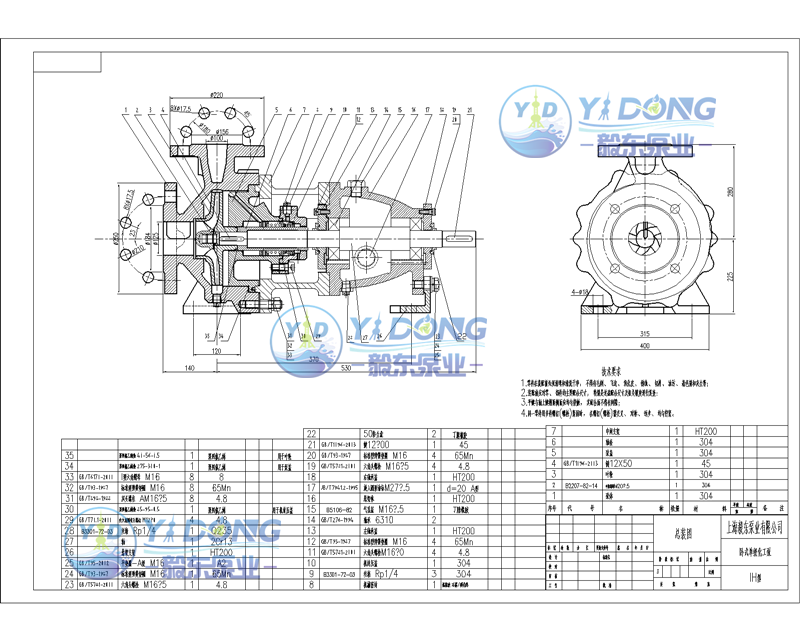

六、结构说明:(附结构设计图)

IH型卧式单级化工泵是全国泵行业采用ISO国际标准联合设计的系列产品,其主要由泵体、叶传输线、密封环、叶轮螺母、泵盖、密封部件、中间支架、轴、悬架部件等组成。泵盖通过止口固定在中间支架上,然后通过泵体与中间支架止口的联接把泵盖夹紧在中间,泵体是轴向吸入,径向排出,脚支承式,可直接固定在底座上。悬架部件通过止口固定固定在中间支架上,并用悬架支架支撑在底座上。为拆卸方便,设计了加长联轴器,检修时可以不拆卸进出口联接管路,泵体和电动机。只需拆下联轴器的中间联接件,即可退出转子部件进行检修。这是国际上通用的一种结构形式。

IH型卧式单级化工泵的轴封型式:泵的密封型式采用填料密封或机械密封,由用户根据需要适用,同时根据需要允许采用适合于ISO3069规定的密封空腔尺寸和其他结构的轴封型式,如带波纹管的机械密封和付叶轮密封等等。泵通过加长联轴器由电动机直接驱动,从电动机端看,按顺时针方向旋转。

填料密封:泵盖内设有填料函,采用软填料密封,填料函内可通入有一定压力的水,供密封冷却,润滑、清洗用。

机械密封:单端面机械密封和双端面机械密封两种型式,密封腔内通入一定压力的水,冲洗磨擦两端面,同时起冷却作用。

七、技术参数:

|

序 号 |

型 号 |

转速n (r/min) |

流量 Q |

扬程 H (m) |

效率 η (%) |

功率(kW) | ||

| (m3/h) | (L/S) | 轴功率 | 电机功率 | |||||

| 1 | IH40-25-125 | 2900 | 4.4 | 1.22 | 21 | 40 | 0.63 | 1.5 |

| 6.3 | 1.80 | 20 | 45 | 0.79 | ||||

| 8.3 | 2.31 | 18 | 43 | 0.95 | ||||

| 1450 | 2.2 | 0.60 | 5.75 | 37 | 0.085 | 0.55 | ||

| 3.25 | 0.90 | 5 | 41 | 0.108 | ||||

| 4.15 | 1.15 | 4.5 | 40 | 0.125 | ||||

| 2 | IH40-25-125A | 2900 | 3.9 | 1.08 | 17.6 | 38 | 0.49 | 1.5 |

| 5.6 | 1.56 | 16 | 42 | 0.58 | ||||

| 7.4 | 2.06 | 14.4 | 40 | 0.72 | ||||

| 3 | IH40-25-160 | 2900 | 4.4 | 1.22 | 33 | 34 | 1.16 | 2.2 |

| 6.3 | 1.80 | 32 | 40 | 1.42 | ||||

| 8.3 | 2.31 | 30 | 39 | 1.71 | ||||

| 1450 | 2.2 | 0.60 | 8.25 | 33 | 0.3 | 0.55 | ||

| 3.25 | 0.90 | 8 | 36 | 0.34 | ||||

| 4.15 | 1.15 | 7.5 | 37 | 0.36 | ||||

| 4 | IH40-25-160A | 2900 | 3.9 | 1.08 | 29 | 32 | 0.96 | 1.5 |

| 5.6 | 1.56 | 28 | 38 | 1.23 | ||||

| 7.4 | 2.06 | 26 | 37 | 1.41 | ||||

| 5 | IH40-25-200 | 2900 | 4.4 | 1.22 | 51 | 26 | 3.16 | 4 |

| 6.3 | 1.80 | 50 | 33 | 3.24 | ||||

| 8.3 | 2.31 | 48 | 32 | 3.57 | ||||

| 1450 | 2.2 | 0.60 | 12.8 | 21 | 0.57 | 1.1 | ||

| 3.25 | 0.90 | 12.5 | 31 | 0.65 | ||||

| 4.15 | 1.05 | 12 | 34 | 0.68 | ||||

| 6 | IH40-25-200A | 2900 | 3.9 | 1.08 | 45 | 26 | 2.96 | 4 |

| 5.6 | 1.56 | 44 | 31 | 3.04 | ||||

| 7.4 | 2.06 | 42 | 30 | 3.37 | ||||

| 7 | IH40-25-250 | 2900 | 4.4 | 1.22 | 82 | 24 | 6.84 | 7.5 |

| 6.3 | 1.80 | 80 | 28 | 6.97 | ||||

| 8.3 | 2.31 | 74 | 27 | 7.71 | ||||

| 1450 | 2.2 | 0.60 | 20.5 | 17 | 1.12 | 1.5 | ||

| 3.25 | 0.90 | 20 | 27 | 1.25 | ||||

| 4.15 | 1.15 | 18.5 | 30 | 1.18 | ||||

| 8 | IH40-25-250A | 2900 | 3.9 | 1.08 | 71.9 | 20 | 6.64 | 7.5 |

| 5.6 | 1.56 | 70 | 32 | 6.74 | ||||

| 7.4 | 2.06 | 68.8 | 34 | 7.51 | ||||

| 1450 | 2 | 0.56 | 18 | 15.4 | 0.67 | 1.1 | ||

| 3 | 0.83 | 17.5 | 25 | 0.72 | ||||

| 3.9 | 1.08 | 16.3 | 27.9 | 0.83 | ||||

| 9 | IH50-32-125 | 2900 | 7.5 | 2.08 | 23 | 43 | 1.09 | 2.2 |

| 12.5 | 3.47 | 20 | 51 | 1.33 | ||||

| 15 | 4.17 | 18 | 49 | 1.5 | ||||

| 1450 | 3.75 | 1.04 | 5.75 | 36 | 0.16 | 0.55 | ||

| 6.3 | 1.75 | 5 | 45 | 0.19 | ||||

| 7.5 | 2.08 | 4.5 | 44 | 0.21 | ||||

| 10 | IH50-32-125A | 2900 | 6.8 | 1.89 | 18.8 | 40 | 0.87 | 1.5 |

| 11.3 | 3.14 | 16.4 | 50 | 1.01 | ||||

| 13.6 | 3.78 | 14.7 | 47 | 1.16 | ||||

| 1450 | 3.4 | 0.94 | 4.7 | 33.3 | 0.13 | 0.55 | ||

| 5.7 | 1.58 | 4.1 | 43 | 0.15 | ||||

| 6.8 | 1.89 | 3.7 | 42 | 0.16 | ||||

| 11 | IH50-32-160 | 2900 | 7.5 | 2.08 | 34.5 | 33 | 2.13 | 3 |

| 12.5 | 3.47 | 32 | 46 | 2.37 | ||||

| 15 | 4.17 | 30 | 50 | 2.45 | ||||

| 1450 | 3.75 | 1.04 | 8.6 | 29 | 0.3 | 0.55 | ||

| 6.3 | 1.75 | 8 | 40 | 0.34 | ||||

| 7.5 | 2.08 | 7.5 | 43 | 0.36 | ||||

| 12 | IH50-32-160A | 2900 | 6.8 | 1.89 | 28.5 | 30 | 1.76 | 3 |

| 11.3 | 3.14 | 26.4 | 44 | 1.85 | ||||

| 13.6 | 3.78 | 24.8 | 48 | 1.91 | ||||

| 1450 | 3.4 | 0.94 | 7.1 | 25.9 | 0.25 | 0.55 | ||

| 5.7 | 1.58 | 6.6 | 37.1 | 0.28 | ||||

| 6.8 | 1.89 | 6.2 | 41 | 0.28 | ||||

| 13 | IH50-32-200 | 2900 | 7.5 | 2.08 | 51.8 | 28 | 3.78 | 5.5 |

| 12.5 | 3.47 | 50 | 39 | 4.36 | ||||

| 15 | 4.17 | 48 | 43 | 4.56 | ||||

| 1450 | 3.75 | 1.04 | 12.9 | 23 | 0.57 | 1.1 | ||

| 6.3 | 1.75 | 12.5 | 33 | 0.65 | ||||

| 7.5 | 2.08 | 12 | 36 | 0.68 | ||||

| 14 | IH50-32-200A | 2900 | 6.8 | 1.89 | 42.7 | 25 | 3.16 | 4 |

| 11.3 | 3.14 | 41 | 38 | 3.24 | ||||

| 13.6 | 3.78 | 39.5 | 41 | 3.57 | ||||

| 1450 | 3.4 | 0.94 | 10.6 | 20 | 0.49 | 0.75 | ||

| 5.7 | 1.58 | 10.3 | 31 | 0.52 | ||||

| 6.8 | 1.89 | 9.9 | 34 | 0.54 | ||||

| 15 | IH50-32-250 | 2900 | 7.5 | 2.08 | 82 | 23 | 7.28 | 11 |

| 12.5 | 3.47 | 80 | 33 | 8.25 | ||||

| 15 | 4.17 | 78.5 | 36.5 | 8.79 | ||||

| 1450 | 3.75 | 1.04 | 20.5 | 17 | 1.23 | 2.2 | ||

| 6.3 | 1.75 | 20 | 27 | 1.27 | ||||

| 7.5 | 2.08 | 19.6 | 31 | 1.29 | ||||

| 16 | IH50-32-250A | 2900 | 7 | 1.94 | 71.9 | 20 | 6.84 | 11 |

| 11.7 | 3.25 | 70 | 32 | 6.97 | ||||

| 14 | 3.89 | 68.8 | 34 | 7.71 | ||||

| 1450 | 3.51 | 0.98 | 18 | 15.4 | 1.12 | 1.5 | ||

| 5.9 | 1.64 | 17.5 | 25 | 1.25 | ||||

| 7.02 | 1.95 | 17.2 | 27.9 | 1.18 | ||||

| 17 | IH50-32-250B | 2900 | 6.6 | 1.83 | 63.6 | 20 | 5.71 | 7.5 |

| 11 | 3.06 | 62 | 30 | 6.19 | ||||

| 13.2 | 3.67 | 60.9 | 33 | 6.64 | ||||

| 18 | IH65-50-125 | 2900 | 15 | 4.17 | 21.3 | 47 | 1.85 | 3 |

| 25 | 6.94 | 20 | 62 | 2.2 | ||||

| 30 | 8.33 | 18.6 | 63 | 2.41 | ||||

| 1450 | 7.5 | 2.08 | 5.4 | 44 | 0.25 | 0.55 | ||

| 12.5 | 3.47 | 5 | 55 | 0.31 | ||||

| 15 | 4.17 | 4.5 | 56 | 0.33 | ||||

| 19 | IH65-50-125A | 2900 | 13.6 | 3.78 | 17.6 | 44 | 1.48 | 2.2 |

| 22.7 | 6.31 | 16.5 | 61 | 1.67 | ||||

| 27.3 | 7.58 | 15.4 | 59.9 | 1.91 | ||||

| 1450 | 6.8 | 1.89 | 4.5 | 41 | 0.2 | 0.55 | ||

| 11.3 | 3.14 | 4.1 | 54 | 0.23 | ||||

| 13.6 | 3.78 | 3.7 | 53 | 0.26 | ||||

| 20 | IH65-50-160 | 2900 | 15 | 4.17 | 34.2 | 44 | 3.18 | 5.5 |

| 25 | 6.94 | 32 | 57 | 3.82 | ||||

| 30 | 8.33 | 30 | 59 | 4.15 | ||||

| 1450 | 7.5 | 2.08 | 8.55 | 39 | 0.45 | 0.75 | ||

| 12.5 | 3.47 | 8 | 51 | 0.53 | ||||

| 15 | 4.17 | 7.5 | 52.5 | 0.58 | ||||

| 21 | IH65-50-160A | 2900 | 13.6 | 3.78 | 28.4 | 41 | 2.65 | 4 |

| 22.7 | 6.31 | 26.5 | 56 | 2.93 | ||||

| 27.3 | 7.58 | 24.8 | 56 | 3.29 | ||||

| 1450 | 6.8 | 1.89 | 7.09 | 35.5 | 0.37 | 0.55 | ||

| 11.3 | 3.14 | 6.6 | 49.6 | 0.41 | ||||

| 13.6 | 3.78 | 6.2 | 49.6 | 0.46 | ||||

| 22 | IH65-40-200 | 2900 | 15 | 4.17 | 53.2 | 41 | 5.3 | 11 |

| 25 | 6.94 | 50 | 52 | 6.55 | ||||

| 30 | 8.33 | 47.6 | 53.5 | 7.27 | ||||

| 1450 | 7.5 | 2.08 | 13.3 | 35 | 0.78 | 1.5 | ||

| 12.5 | 3.47 | 12.5 | 46 | 0.93 | ||||

| 15 | 4.17 | 11.9 | 47.5 | 1.02 | ||||

| 23 | IH65-40-200A | 2900 | 13.6 | 3.78 | 43.9 | 38 | 4.28 | 7.5 |

| 22.7 | 6.31 | 41 | 50 | 5.07 | ||||

| 27.3 | 7.58 | 39.3 | 51 | 5.73 | ||||

| 1450 | 6.8 | 1.89 | 11 | 31.8 | 0.64 | 1.1 | ||

| 11.3 | 3.14 | 10.3 | 44 | 0.72 | ||||

| 13.6 | 3.78 | 9.8 | 44.8 | 0.81 | ||||

| 24 | IH65-40-250 | 2900 | 15 | 4.17 | 81.2 | 34 | 9.76 | 15 |

| 25 | 6.94 | 80 | 46 | 11.84 | ||||

| 30 | 8.33 | 78.4 | 50 | 12.8 | ||||

| 1450 | 7.5 | 2.08 | 20.3 | 28 | 1.48 | 3 | ||

| 12.5 | 3.47 | 20 | 39 | 1.75 | ||||

| 15 | 4.17 | 19.6 | 43 | 1.86 | ||||

| 25 | IH65-40-250A | 2900 | 14 | 3.89 | 74.8 | 31 | 9.21 | 15 |

| 23.4 | 6.50 | 71 | 45 | 10.1 | ||||

| 28 | 7.78 | 68.6 | 47 | 11.13 | ||||

| 1450 | 7 | 1.94 | 17.8 | 25 | 1.35 | 2.2 | ||

| 11.7 | 3.25 | 17.5 | 37.9 | 1.47 | ||||

| 14 | 3.89 | 17.2 | 40 | 1.64 | ||||

| 26 | IH65-40-250B | 2900 | 13.2 | 3.67 | 62.8 | 31 | 7.29 | 11 |

| 22 | 6.11 | 61.8 | 44 | 8.42 | ||||

| 26.4 | 7.33 | 53 | 45 | 8.45 | ||||

| 27 | IH65-40-315 | 2900 | 15 | 4.17 | 126.8 | 28 | 18.5 | 30 |

| 25 | 6.94 | 125 | 39 | 21.8 | ||||

| 30 | 8.33 | 124 | 42.5 | 23.9 | ||||

| 1450 | 7.5 | 2.08 | 32.4 | 22 | 3.03 | 5.5 | ||

| 12.5 | 3.47 | 32 | 33 | 3.3 | ||||

| 15 | 4.17 | 31.7 | 37 | 3.5 | ||||

| 28 | IH65-40-315A | 2900 | 14 | 3.89 | 111.2 | 25 | 156.97 | 30 |

| 23.4 | 6.50 | 109.5 | 35 | 18.36 | ||||

| 28 | 7.78 | 108.8 | 40 | 20.75 | ||||

| 1450 | 7 | 1.94 | 28.4 | 22 | 2.46 | 4 | ||

| 11.7 | 3.25 | 28 | 33 | 2.71 | ||||

| 14 | 3.89 | 27.8 | 37 | 2.87 | ||||

| 29 | IH65-40-315B | 2900 | 13.2 | 3.68 | 98 | 24 | 14.69 | 22 |

| 22 | 6.11 | 96.5 | 37 | 15.63 | ||||

| 26.4 | 7.33 | 95.6 | 39 | 17.67 | ||||

| 30 | IH80-65-125 | 2900 | 30 | 8.33 | 23.2 | 60 | 3.16 | 5.5 |

| 50 | 13.9 | 20 | 69 | 3.95 | ||||

| 60 | 16.7 | 17.6 | 67 | 4.29 | ||||

| 1450 | 15 | 4.17 | 5.8 | 54 | 0.44 | 0.75 | ||

| 25 | 6.94 | 5 | 64 | 0.53 | ||||

| 30 | 8.33 | 4.4 | 62 | 0.58 | ||||

| 31 | IH80-65-125A | 2900 | 27.2 | 7.56 | 19.1 | 57 | 2.48 | 4 |

| 45.3 | 12.58 | 16.5 | 67 | 3.04 | ||||

| 54.4 | 15.11 | 14.5 | 64 | 3.36 | ||||

| 1450 | 13.6 | 3.78 | 4.8 | 51 | 0.35 | 0.55 | ||

| 22.6 | 6.28 | 4.1 | 62 | 0.41 | ||||

| 27.2 | 7.56 | 3.6 | 59 | 0.45 | ||||

| 32 | IH80-65-160 | 2900 | 30 | 8.33 | 36 | 57 | 5.16 | 11 |

| 50 | 13.9 | 32 | 67 | 6.51 | ||||

| 60 | 16.7 | 28.4 | 65 | 7.14 | ||||

| 1450 | 15 | 4.17 | 9 | 50 | 0.74 | 1.5 | ||

| 25 | 6.94 | 8 | 62 | 0.88 | ||||

| 30 | 8.33 | 7.2 | 62 | 0.95 | ||||

| 33 | IH80-65-160A | 2900 | 27.2 | 7.56 | 29.7 | 54 | 4.08 | 7.5 |

| 45.3 | 12.58 | 26.4 | 65 | 5.02 | ||||

| 54.4 | 15.11 | 2.34 | 62 | 5.59 | ||||

| 1450 | 13.6 | 3.78 | 7.4 | 47.3 | 0.58 | 1.1 | ||

| 22.6 | 6.28 | 6.6 | 60 | 0.68 | ||||

| 27.2 | 7.56 | 5.9 | 59 | 0.74 | ||||

| 34 | IH80-50-200 | 2900 | 30 | 8.33 | 55.2 | 53 | 8.51 | 15 |

| 50 | 13.9 | 50 | 63 | 10.8 | ||||

| 60 | 16.7 | 45.2 | 62 | 11.9 | ||||

| 1450 | 15 | 4.17 | 13.5 | 44 | 1.25 | 2.2 | ||

| 25 | 6.94 | 12.5 | 57 | 1.49 | ||||

| 30 | 8.33 | 11.5 | 58 | 1.62 | ||||

| 35 | IH80-50-200A | 2900 | 27.2 | 7.56 | 45.4 | 50 | 6.73 | 11 |

| 45.3 | 12.58 | 41 | 61 | 8.29 | ||||

| 54.4 | 15.11 | 37.2 | 59 | 9.35 | ||||

| 1450 | 13.6 | 3.78 | 11.1 | 41 | 1 | 2.2 | ||

| 22.6 | 6.28 | 10.3 | 56.1 | 1.14 | ||||

| 27.2 | 7.56 | 9.5 | 55 | 1.28 | ||||

| 36 | IH80-50-250 | 2900 | 30 | 8.33 | 84 | 43 | 16 | 30 |

| 50 | 13.9 | 80 | 53 | 20.6 | ||||

| 60 | 16.7 | 75 | 54 | 22.7 | ||||

| 1450 | 15 | 4.17 | 21 | 40 | 2.15 | 4 | ||

| 25 | 6.94 | 20 | 50 | 2.72 | ||||

| 30 | 8.33 | 18.8 | 51 | 3.01 | ||||

| 37 | IH80-50-250A | 2900 | 27.2 | 7.56 | 69 | 42 | 12.18 | 22 |

| 45.3 | 12.58 | 65.7 | 52 | 15.61 | ||||

| 54.4 | 15.11 | 61.6 | 52 | 17.57 | ||||

| 1450 | 13.6 | 3.78 | 17.3 | 40 | 1.6 | 3 | ||

| 22.6 | 6.28 | 16.4 | 49 | 2.07 | ||||

| 27.2 | 7.56 | 15.4 | 50 | 2.28 | ||||

| 38 | IH80-50-315 | 2900 | 30 | 8.33 | 128 | 38 | 27.5 | 45 |

| 50 | 13.9 | 125 | 50 | 34.1 | ||||

| 60 | 16.7 | 123 | 53 | 37.9 | ||||

| 1450 | 15 | 4.17 | 32.5 | 37 | 3.59 | 7.5 | ||

| 25 | 6.94 | 32 | 48 | 4.54 | ||||

| 30 | 8.33 | 31.5 | 52 | 4.94 | ||||

| 39 | IH80-50-315A | 2900 | 27.2 | 7.56 | 105 | 37 | 21 | 37 |

| 45.3 | 12.58 | 102.6 | 48 | 26.4 | ||||

| 54.4 | 15.11 | 101 | 50 | 28.94 | ||||

| 1450 | 13.6 | 3.78 | 26.3 | 36 | 2.71 | 5.5 | ||

| 22.6 | 6.28 | 25.7 | 46 | 3.46 | ||||

| 27.2 | 7.56 | 25.2 | 50 | 3.74 | ||||

| 40 | IH100-80-125 | 2900 | 60 | 16.7 | 23.7 | 65 | 5.96 | 11 |

| 100 | 27.8 | 20 | 73 | 7.47 | ||||

| 120 | 33.3 | 16.3 | 69 | 7.72 | ||||

| 1450 | 30 | 8.33 | 5.7 | 58 | 0.8 | 1.5 | ||

| 50 | 13.9 | 5 | 69 | 0.99 | ||||

| 60 | 16.7 | 4.1 | 68 | 0.99 | ||||

| 41 | IH100-80-125A | 2900 | 55 | 15.28 | 19.4 | 62 | 4.68 | 7.5 |

| 91.8 | 25.5 | 16.8 | 71 | 5.92 | ||||

| 109 | 30.28 | 13.7 | 67 | 6.07 | ||||

| 1450 | 27.5 | 7.64 | 5 | 56 | 0.67 | 1.1 | ||

| 45.9 | 12.75 | 4.2 | 67 | 0.78 | ||||

| 54.5 | 15.13 | 3.4 | 65 | 0.78 | ||||

| 42 | IH100-80-160 | 2900 | 60 | 16.7 | 37 | 60 | 10.1 | 15 |

| 100 | 27.8 | 32 | 73 | 11.9 | ||||

| 120 | 33.3 | 28 | 73 | 12.5 | ||||

| 1450 | 30 | 8.33 | 9.25 | 58 | 1.3 | 2.2 | ||

| 50 | 13.9 | 8 | 69 | 1.58 | ||||

| 60 | 16.7 | 7 | 68 | 1.68 | ||||

| 43 | IH100-80-160A | 2900 | 54.6 | 15.17 | 30.6 | 57 | 7.98 | 15 |

| 91 | 25.28 | 26.5 | 71 | 9.25 | ||||

| 109.2 | 30.33 | 23.2 | 70.4 | 9.85 | ||||

| 1450 | 27.3 | 7.58 | 7.66 | 55.3 | 1.03 | 1.5 | ||

| 45.5 | 12.64 | 6.6 | 67 | 0.22 | ||||

| 54.6 | 15.17 | 5.8 | 65.3 | 1.32 | ||||

| 44 | IH100-65-200 | 2900 | 60 | 16.7 | 56 | 63 | 14.5 | 22 |

| 100 | 27.8 | 50 | 72 | 18.9 | ||||

| 120 | 33.3 | 44 | 71 | 20.3 | ||||

| 1450 | 30 | 8.33 | 14 | 60 | 1.91 | 4 | ||

| 50 | 13.9 | 12.5 | 68 | 2.5 | ||||

| 60 | 16.7 | 11 | 63 | 2.85 | ||||

| 45 | IH100-65-200A | 2900 | 54.6 | 15.17 | 46.5 | 60.1 | 11.51 | 18.5 |

| 91 | 25.28 | 41.5 | 70 | 14.7 | ||||

| 109.2 | 30.33 | 36.6 | 68 | 16 | ||||

| 1450 | 27.3 | 7.58 | 11.6 | 57 | 1.51 | 3 | ||

| 45.5 | 12.64 | 10.3 | 66 | 1.93 | ||||

| 54.6 | 15.17 | 9.1 | 60.1 | 2.25 | ||||

| 46 | IH100-65-250 | 2900 | 60 | 16.7 | 88 | 57 | 25.2 | 37 |

| 100 | 27.8 | 80 | 68 | 32.1 | ||||

| 120 | 33.3 | 74 | 67 | 36.1 | ||||

| 1450 | 30 | 8.33 | 22 | 50 | 3.63 | 5.5 | ||

| 50 | 13.9 | 20 | 63 | 4.33 | ||||

| 60 | 16.7 | 18.5 | 64 | 4.73 | ||||

| 47 | IH100-65-250A | 2900 | 56.1 | 15.58 | 77 | 54 | 21.8 | 37 |

| 93.5 | 25.97 | 70 | 65 | 27.44 | ||||

| 112.2 | 31.17 | 64.7 | 64 | 30.91 | ||||

| 1450 | 28 | 7.79 | 19.2 | 47 | 3.12 | 5.5 | ||

| 45.5 | 12.64 | 17.4 | 61 | 3.53 | ||||

| 56 | 15.56 | 16.2 | 60.9 | 4.06 | ||||

| 48 | IH100-65-250B | 2900 | 25.7 | 14.65 | 67.9 | 53.3 | 18.29 | 30 |

| 87.8 | 24.39 | 61.7 | 64 | 23.1 | ||||

| 105.4 | 29.28 | 57 | 62.9 | 26.03 | ||||

| 49 | IH100-65-315 | 2900 | 60 | 16.7 | 132 | 48 | 44.9 | 75 |

| 100 | 27.8 | 125 | 62 | 54.9 | ||||

| 120 | 33.3 | 119 | 64 | 60.8 | ||||

| 1450 | 30 | 8.33 | 33.5 | 44 | 6.22 | 11 | ||

| 50 | 13.9 | 32 | 58 | 7.52 | ||||

| 60 | 16.7 | 30.5 | 60 | 8.31 | ||||

| 50 | IH100-65-315A | 2900 | 56.1 | 15.58 | 115.5 | 45 | 39.2 | 55 |

| 93.5 | 25.97 | 109 | 61 | 45.53 | ||||

| 112.2 | 31.17 | 104 | 61 | 52.13 | ||||

| 1450 | 28 | 7.789 | 29.3 | 41 | 5.46 | 11 | ||

| 46.5 | 12.92 | 28 | 56 | 6.33 | ||||

| 7.5 | ||||||||

| 56 | 15.56 | 26.7 | 57 | 7.15 | ||||

| 51 | IH100-65-315B | 2900 | 52.7 | 14.64 | 102 | 44 | 33.29 | 55 |

| 88 | 24.44 | 97 | 60 | 38.77 | ||||

| 105.4 | 29.28 | 92 | 60 | 44.04 | ||||

| 52 | IH125-100-200 | 2900 | 120 | 33.3 | 61 | 68 | 29.3 | 45 |

| 200 | 55.6 | 50 | 77 | 35.4 | ||||

| 240 | 66.7 | 41 | 70 | 38.3 | ||||

| 1450 | 60 | 16.7 | 15.3 | 64 | 3.89 | 7.5 | ||

| 100 | 27.8 | 12.5 | 73 | 4.66 | ||||

| 120 | 33.3 | 10.3 | 66 | 5.08 | ||||

| 53 | IH125-100-200A | 2900 | 109.1 | 30.31 | 50.5 | 64.9 | 23.13 | 37 |

| 182 | 50.56 | 41.4 | 75 | 27.38 | ||||

| 218.2 | 60.61 | 34 | 67.1 | 30.13 | ||||

| 1450 | 54.7 | 15.19 | 12.6 | 61 | 3.08 | 5.5 | ||

| 91 | 28.28 | 10.3 | 71 | 3.6 | ||||

| 109.4 | 30.39 | 8.5 | 63 | 4.02 | ||||

| 54 | IH125-100-250 | 2900 | 120 | 33.3 | 90 | 62 | 47.5 | 75 |

| 200 | 55.6 | 80 | 75 | 58.1 | ||||

| 240 | 66.7 | 73 | 74 | 64.5 | ||||

| 1450 | 60 | 16.7 | 22.5 | 59 | 6.23 | 11 | ||

| 100 | 27.8 | 20 | 72 | 7.56 | ||||

| 120 | 33.3 | 18.3 | 71 | 8.4 | ||||

| 55 | IH125-100-250A | 2900 | 112 | 31.11 | 78 | 59 | 40.35 | 75 |

| 186.5 | 51.81 | 69.5 | 73 | 48.35 | ||||

| 224 | 62.22 | 63.5 | 71 | 54.59 | ||||

| 1450 | 56 | 15.56 | 19.5 | 56 | 5.31 | 11 | ||

| 93 | 25.83 | 17.4 | 70 | 6.29 | ||||

| 7.5 | ||||||||

| 112 | 31.11 | 15.9 | 68 | 7.13 | ||||

| 56 | IH125-100-250B | 2900 | 105.5 | 29.31 | 69 | 58 | 34.2 | 55 |

| 175.5 | 48.75 | 61.5 | 71 | 41.42 | ||||

| 211 | 58.61 | 56 | 69.9 | 46.06 | ||||

| 57 | IH125-100-315 | 2900 | 120 | 33.3 | 132.5 | 52.6 | 82.4 | 110 |

| 200 | 55.6 | 125 | 72 | 94.6 | ||||

| 240 | 66.7 | 120 | 75 | 104.6 | ||||

| 1450 | 60 | 16.7 | 33.5 | 53 | 10.3 | 22 | ||

| 100 | 27.8 | 32 | 65 | 13.4 | ||||

| 120 | 33.3 | 30.5 | 66 | 15.1 | ||||

| 58 | IH125-100-315A | 2900 | 112 | 31.11 | 115.2 | 52 | 67.63 | 90 |

| 186.5 | 51.81 | 108.7 | 71 | 77.81 | ||||

| 224 | 62.22 | 104.3 | 72 | 88.42 | ||||

| 1450 | 56 | 15.56 | 28.8 | 52 | 8.45 | 15 | ||

| 93 | 25.83 | 27.2 | 64 | 10.77 | ||||

| 112 | 31.11 | 26.1 | 65 | 12.25 | ||||

| 59 | IH125-100-400 | 1450 | 60 | 16.7 | 52 | 48 | 17.7 | 30 |

| 100 | 27.8 | 50 | 55 | 24.8 | ||||

| 120 | 33.3 | 48.5 | 62 | 25.6 | ||||

| 60 | IH125-100-400A | 1450 | 56 | 15.56 | 45 | 43 | 15.97 | 30 |

| 93 | 25.83 | 43.2 | 54 | 20.27 | ||||

| 112 | 31.11 | 41.9 | 60 | 21.31 | ||||

| 61 | IH150-125-250 | 1450 | 120 | 33.3 | 24.8 | 66 | 12.3 | 18.5 |

| 200 | 55.6 | 20 | 77 | 14.2 | ||||

| 240 | 66.7 | 15 | 68 | 14.4 | ||||

| 62 | IH150-125-250A | 1450 | 109.1 | 30.28 | 20.5 | 62.5 | 9.75 | 15 |

| 182 | 50.56 | 16.5 | 75 | 10.91 | ||||

| 218.2 | 60.61 | 12.4 | 65.2 | 11.31 | ||||

| 63 | IH150-125-315 | 1450 | 120 | 33.3 | 36.3 | 63 | 18.8 | 30 |

| 200 | 55.6 | 32 | 75 | 23.3 | ||||

| 240 | 66.7 | 28.5 | 72 | 25.9 | ||||

| 64 | IH150-125-315A | 1450 | 109.1 | 30.28 | 30 | 60 | 14.85 | 22 |

| 182 | 50.56 | 25.5 | 73 | 17.32 | ||||

| 218.2 | 60.61 | 23.5 | 69 | 20.23 | ||||

| 65 | IH150-125-315B | 1450 | 99 | 27.5 | 24.7 | 59 | 11.29 | 18.5 |

| 165 | 45.83 | 22 | 72 | 13.74 | ||||

| 198 | 55 | 19.4 | 69 | 15.17 | ||||

| 66 | IH150-125-400 | 1450 | 120 | 33.3 | 57.5 | 61 | 30.8 | 55 |

| 200 | 55.6 | 50 | 70 | 38.9 | ||||

| 240 | 66.7 | 44 | 63 | 45.7 | ||||

| 67 | IH150-125-400A | 1450 | 109.1 | 30.28 | 47.5 | 58 | 24.35 | 37 |

| 182 | 50.56 | 41 | 68 | 29.94 | ||||

| 218.2 | 60.61 | 36.5 | 60 | 36.17 | ||||

| 68 | IH150-125-400B | 1450 | 99 | 27.5 | 39.1 | 57 | 18.51 | 30 |

| 165 | 45.83 | 34 | 67 | 22.82 | ||||

| 198 | 55 | 29.9 | 58 | 27.81 | ||||

| 69 | IH200-150-250 | 1450 | 240 | 66.7 | 23 | 70 | 21.5 | 37 |

| 400 | 111.1 | 20 | 79 | 27.6 | ||||

| 160 | 127.8 | 18 | 80 | 28.2 | ||||

| 70 | IH200-150-250A | 1450 | 218.2 | 60.61 | 18.9 | 67 | 16.77 | 30 |

| 363 | 100.83 | 16.5 | 79 | 20.66 | ||||

| 418 | 116.1 | 14.8 | 78 | 21.61 | ||||

| 71 | IH200-150-315 | 1450 | 240 | 66.7 | 35.6 | 67 | 34.8 | 55 |

| 400 | 111.1 | 32 | 79 | 44.2 | ||||

| 460 | 127.8 | 29.4 | 77 | 47.9 | ||||

| 72 | IH200-150-315A | 1450 | 218.2 | 60.61 | 29.4 | 64 | 27.31 | 45 |

| 363 | 100.83 | 25.5 | 77 | 32.76 | ||||

| 418 | 116.1 | 24.3 | 74 | 37.4 | ||||

| 73 | IH200-150-315B | 1450 | 197.7 | 54.92 | 24.1 | 63 | 20.61 | 37 |

| 329 | 91.39 | 21.6 | 76 | 25.48 | ||||

| 378.8 | 105.22 | 19.7 | 73 | 27.86 | ||||

| 74 | IH200-150-400 | 1450 | 240 | 66.7 | 55.8 | 67 | 54.5 | 90 |

| 400 | 111.1 | 50 | 78 | 69.9 | ||||

| 460 | 127.8 | 47 | 75 | 78.6 | ||||

| 75 | IH200-150-400A | 1450 | 218.2 | 60.61 | 46 | 64 | 42.74 | 75 |

| 363 | 100.83 | 41 | 76 | 53.36 | ||||

| 418 | 116.1 | 38.8 | 72 | 61.38 | ||||

| 76 | IH200-150-400B | 1450 | 197.7 | 54.92 | 37.7 | 63 | 32.24 | 55 |

| 329 | 91.39 | 33.8 | 75 | 40.4 | ||||

| 378.8 | 105.22 | 31.8 | 71 | 46.23 | ||||

八、注意事项:

IH型卧式单级化工泵可根据不同的使用条件安装不同形式的机械密封,(如内装单端面平衡和非平衡型,双端面平衡型及非平平衡型,外装式机械密封等。)根据所选用密封型式的不同,其使用方法和注意事项也有所不同。下面仅提几点一般应注意的事项。

1.由于机械密封一般适用在清洁的,无悬浮颗粒介质中使用,因此,对新安装的管路系统和储液灌,应认真冲洗干净,严防固体杂质进入机械密封端面而使密封失效。

2.在易结晶的介质中,使用机械密封应注意经常冲洗。停车后重新起动前,要将机械密封上的结晶清洗干净。

3.拆卸机械密封应仔细,不许用手锤,铁器等敲击,以免破坏动、静环密封面。

4.如果有污垢拆不下来时,应设法清除污垢,冲洗干净后再进行拆卸,以免损坏密封元件。

5.安装机械密封前,应检查所有密封元件是否有失效或损坏,如有则应重新修复或更换。

6.应严格检查动环与静环的相对磨擦密封面,不允许有任何细微的划痕、碰伤等缺陷。所有另部件,包括泵体,叶轮,密封腔等在装配前均应冲洗干净,尤其是动、静环庙面,要用清洁,柔软的布或棉纱认真擦拭干净,然后涂上一层清洁的油脂或机油。

7.装配中要注意消除偏差,紧固螺钉时,要均匀拧紧,避免发生偏斜,使密封失效。

8.正确调整弹簧的压缩量,泵安装好以后,以手扳动转子时,应感觉到密封弹簧既有一定的压缩量,而又能轻快、灵活地转动没有咬紧的感觉。如感觉太紧或盘不动,则应适当调松一些。

9.对有外部冲洗的机械密封,起动前应先开启冲洗液,使卧式单级化工泵密封腔内充满密封液。停车时,先停泵,后关密封冲洗液。

九、联系我们:

公司名称:上海毅东泵业有限公司

公司官网:http://www.shyidong.com

公司电话:021-51860791

企业 QQ:1951087218

邮 箱:1951087218@qq.com

业务手机:15317715120 18221891460

地 址:上海市浦东新区万祥镇宏祥北路83弄

如果您有毅东相关产品的需求,欢迎您及时致电、在线QQ/微信等方式与我们取得联系,我们将竭诚为您服务,让您采购更加合理高效的优质产品,上海毅东泵业期待与您长期合作,希望我们能够合作愉快!

注:1.本网页显示的泵图片、尺寸、标准、参数表等样本信息,都为上海毅东泵业有限公司所有,请勿转载,转载必究。

2.由于编辑水平有限,以上信息仅作参考之用,错误和不妥之处在所难免,真诚希望您批评指正。

| 上一条记录:没有记录 |  | 下一条记录:点击查看下一款 |

IH型卧式单级化工泵

IH型卧式单级化工泵